Electrification Ready

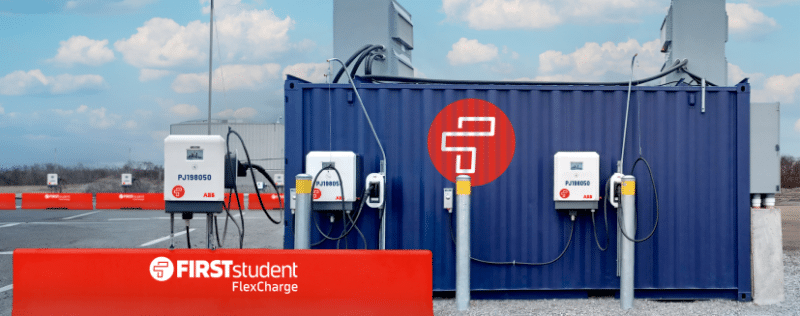

There is much talk about electric school buses and the benefits they will bring. First Student is leading the way in fleet electrification.

contact usThe undisputed leader in fleet electrification

No one has more EV buses on the road or EV miles driven than First Student. While many companies talk about their future plans we are breaking ground in the electric school bus industry.

Most electric buses deployed in North America

More than 3 million miles driven in electric buses

Secured for our customers in EPA funding